Adhering to the new concept of creating a successful future, the world's first ES series large-scale servo direct drive plate rolling machine came into being in the new Ezhong·EZHONG grand release! This new equipment which carries the labor sweat and wisdom of new EZHONG - EZHONG caused quite a stir as soon as it debuted - it will be on display at the 4.11 Jinan International Machine Tool Exhibition, accepting to observe by the international market industry insiders.

Today, let's take the lead in the 4.11 Jinan International Machine Tool Exhibition, and take a look at the core features of the ES series large-scale servo direct-drive plate bending machine in advance through the article!

The machine adopts the structure that the left main cylinder is placed below and the right main cylinder is placed above. The whole machine is beautiful, firm and stable, which is especially convenient for cylinder discharge after rolling. At the same time, it has a wide field of vision and is easy to operate; In addition, the seal replacement is simple&quick, and the main oil cylinder replacement is completed within only 2 hours.

Small center distance is used for rolling small diameter cylinders, large center distances can be used for large cylinders workpieces; The use of different center distances greatly improves the plate range; At the same time, smaller center distances can improve workpiece rolling and rounder accuracy; The horizontal moving device of lower rollers on the front and rear sides adopts a direct drive motor and a reducer to drive nut&screw which move the lower rollers, so as to increase and decrease the center distance, and at the same time, two lower rollers can be offset forward or backward as a whole. It is convenient for the plate pre-bending, which is very convenient and flexible; Mobile device adopts the precision mechanical screw structure. After debugging the zero position, compared with the hydraulic cylinder, the precision is higher and stability is better. When use on site, the whole machine is directly placed, there is no need for secondary adjustment of machine zero position.

Because left main cylinder adopts a down-mounted structure, the inverting frame size is greatly reduced compared to traditional plate rolling machine. Because the inverting frame of center gravity is lowered, the stability is greatly increased, at the same time, it is very beautiful and has a wide field of vision; When small inverting frame is rolling, the cone advantage is also very obvious.

The positioning of traditional balance cylinder is troublesome, and concrete pouring has to be carried out; the balance cylinder of our machine is ingeniously designed to keep up with the follow-up of the rollers, and it does not require a cement foundation, saving cost and time.

The main drive system is this model highlight. The main drive is driven by a direct-drive motor and uses an expensive planetary gear reducer. The volume is reduced, and transmission efficiency is greatly improved; the problem of the lower roller slipping caused by the main drive of the upper roller and three work rollers being out of synchronization is solved, the coiling accuracy is improved, slippage and vibration are avoided, and machine service life is prolonged. Due to the use of a direct-drive motor, the precision achieves closed-loop control of position, speed and torque; It has good high-speed performance, strong anti-overload capability, and can withstand loads three times the rated torque. It is especially applicable; low-speed operation is stable, the dynamic response time of motor acceleration and deceleration is short, generally within tens of milliseconds; the noise is significantly reduced. Higher efficiency while avoiding concrete pouring while the reducer is in place.

The oil circuit adopts a high and low pressure pumps combination. According to the characteristics of the two main oil cylinders being placed up and down, the design is beautiful and the layout is reasonable. The main oil cylinder speed synchronization is very good when it goes up and down, and running speed is reasonable. Pressure maintaining, pressure relief, and quick return functions. The overall operation is smooth, low noise and no leakage.

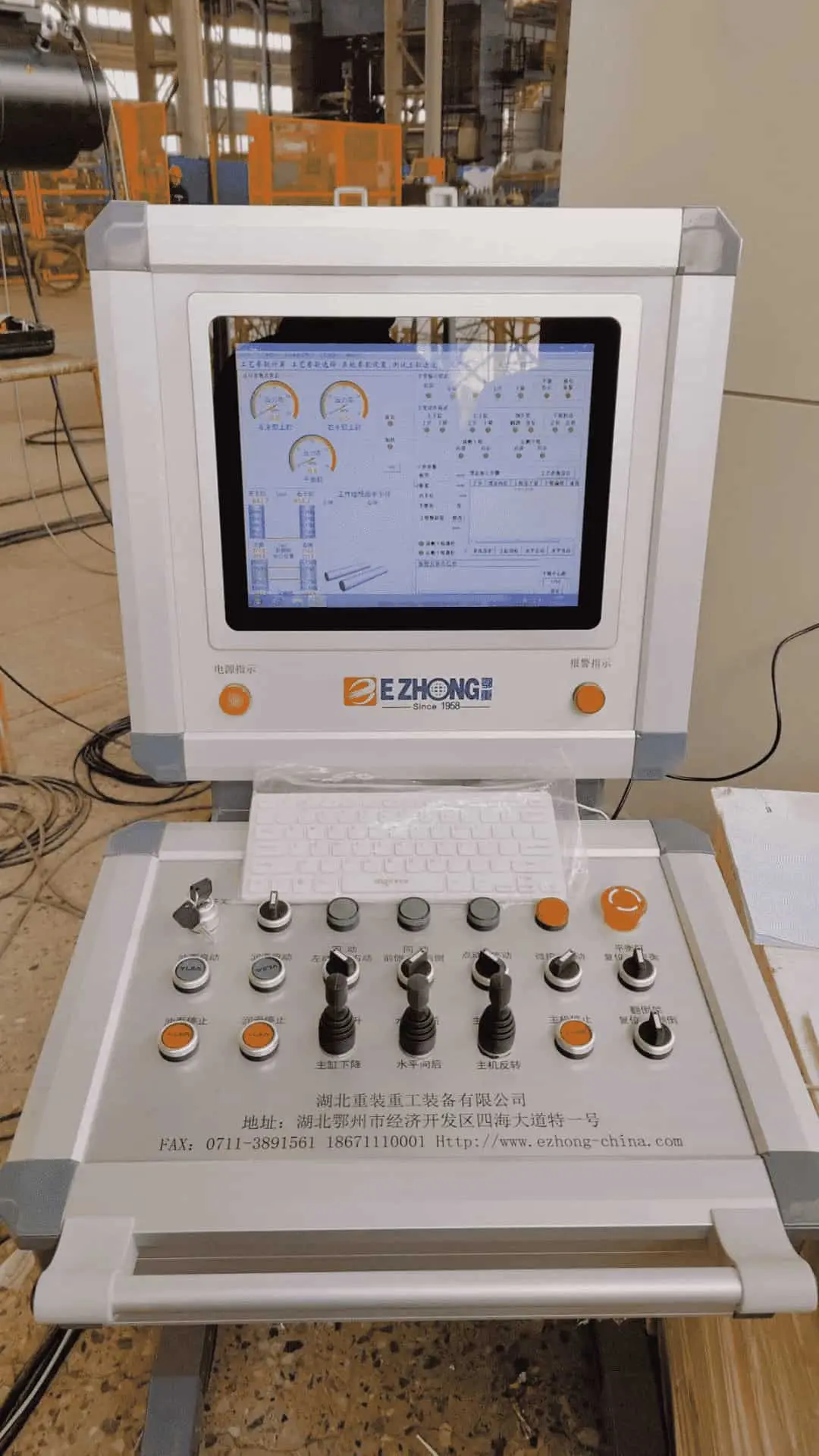

The control system is controlled by a touch-type integrated industrial computer and Siemens PLC. The main interface is beautiful&elegant, which shows precisely the position data of machine each part, the each oil cylinder pressure data, the solenoid valve and other components working status, and the alarm prompt bar are displayed in real time. Various alarms&each travel switch in place status reminder. At the same time, system has calculation & process storage and calling calculation. Greatly improve machine efficiency and facilitate operation. The system also has remote control and console switching and interlocking functions, and one person can complete rolling process.

Now that the secret is revealed, are you also looking forward to its arrival? Let us pay attention to the brand of New Ezhong·Hubei Heavy Industry Equipment, pay attention to the wonderful performance at the 4.11 Jinan International Machine Tool Exhibition, and witness the new look of New Ezhong·EZHONG in 2022!