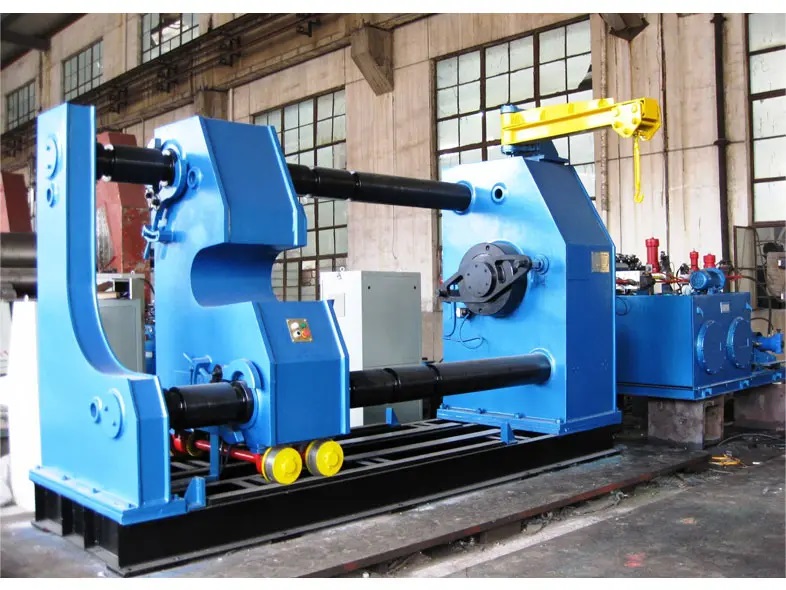

The Power of CNC Plate Rollers in Metalworking

The Power of CNC Plate Rollers in Metalworking

Revolutionizing Fabrication PrecisionIn the dynamic world of metalworking, the advent of Computer Numerical Control (CNC) technology has brought about a transformative era, redefining the capabilities...