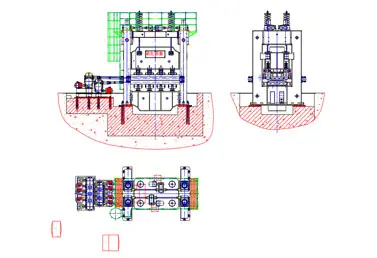

Adopting a reinforced frame structure, the stress during leveling is evenly distributed internally, the frame has a streamlined appearance, and the overall rigidity is enhanced, enabling stable operation under full-load conditions without additional foundation reinforcement;

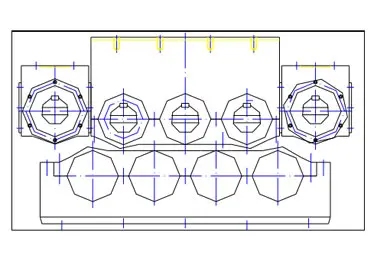

The roll gap adjustment mechanism and pressure control system are integrated, adopting modular design, and driven by high-precision servo motors, allowing the working rolls to achieve precise positioning and smooth adjustment according to different plate thickness requirements.